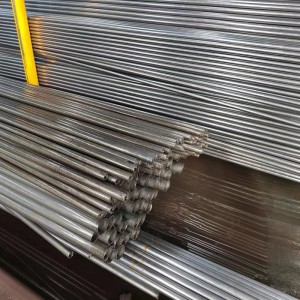

20Cr Cold Rolled Precision Alloy Seamless Steel Tube/Pipe

Short Description:

20Cr alloy steel pipe is a kind of high-precision steel pipe material after cold drawing or hot rolling treatment. Because the inner and outer walls of precision steel pipes have no oxide layer, no leakage under high pressure, high precision, high finish, no deformation during cold bending, flaring, flattening and no cracks, etc., 20cr precision steel pipes are widely used in automobiles, motorcycles, electric vehicles, petrochemical, electric power, ships, aerospace, bearings, and pneumatic components.

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for 20Cr Cold Rolled Precision Alloy Seamless Steel Tube/Pipe, We welcome new and previous shoppers from all walks of existence to contact us for long term organization relationships and acquiring mutual success!

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for China 20Cr Alloy Seamless Steel Pipe Precision Bright Tube, Only for accomplishing the good-quality product to meet customer’s demand, all of our products and solutions have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

|

Grade |

C |

Si |

Mn |

Cr |

Mo |

Ni |

|

20Cr |

0.18-0.24 |

0.17-0.37 |

0.50-0.80 |

0.70-1.00 |

/ |

/ |

|

Grade |

Tensile Strength(MPa) |

Yield Strength(MPa) |

% Elongation in 2 in.(50mm) min |

|

20Cr |

785-835 |

490-540 |

10 |

20Cr alloy steel pipe can improve the material utilization rate, simplify the manufacturing process, save materials and processing time, such as rolling bearing rings, jack sleeves, etc.

20Cr alloy steel pipe is also an indispensable material for various conventional weapons, and the barrel and barrel of the gun are made of steel pipe.

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing or Cold Rolling, On line inspection

5. Heat Treatment

6. Straightening/Cutting to specified length/Finished Measuring Inspection

7. Quality Testing in own lab with Tensile Strength, Yield Strength, Elongation, Hardness, Straightness, etc.

8. Packing and Stocking.

100% Eddy Current Testing.

100% Size Tolerance Checking.

100% Tube surface checking to avoid surface defects

Hot Rolled, Annealed, Normalized, Quenched and Tempered

Packaging

1. Bundle packing

2. Beveled end or plain end or varnished as per buyer’s required

3. Marking: as per customer’s requests

4. Painting varnish coating on the pipe

5. Plastic caps at ends

Delivery time

With 15-30 days after full payment received

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet.

20Cr Cold Rolled Precision Alloy Seamless Steel Tube/Pipe

We welcome new and previous shoppers from all walks of existence to contact us for long term organization relationships and acquiring mutual success!

China 20Cr Alloy Seamless Steel Pipe Precision Bright Tube

Only for accomplishing the good-quality product to meet customer’s demand, all of our products and solutions have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!