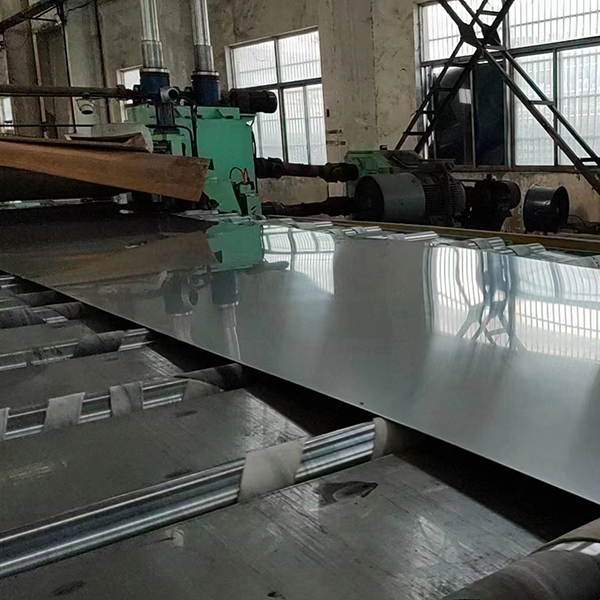

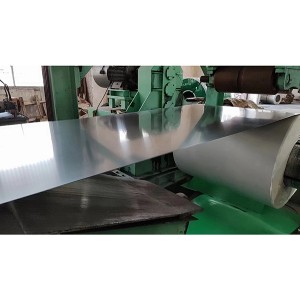

316 /316L Stainless Steel Plate

Short Description:

316/316L stainless steel is a type of austenitic stainless steel with a molybdenum content of 2-3% due to the addition of molybdenum in the steel. The addition of molybdenum makes the metal more resistant to pitting and corrosion, and improves its high-temperature resistance. The solid solution state is non-magnetic, and the cold-rolled product has a good appearance gloss. 316/316L stainless steel also has good resistance to chloride corrosion, so it is commonly used in marine environments. In addition, 316/316L stainless steel is commonly used as a material for pulp and paper equipment, heat exchangers, dyeing equipment, film washing equipment, pipelines, exterior buildings in coastal areas, as well as watch chains and cases for high-end watches.

1. There are many reasons why the surface processing of stainless steel is important in the field of construction applications. The requirement for a smooth surface in a corrosive environment is because the surface is smooth and not prone to scaling. The deposition of dirt can cause stainless steel to rust and even cause corrosion.

2. In the spacious lobby, stainless steel is the most commonly used material for elevator decorative panels. Although the surface fingerprints can be wiped off, they affect aesthetics. Therefore, it is best to choose a suitable surface to prevent fingerprints from leaving.

3.Hygiene conditions are important for many industries, such as food processing, catering, brewing, and chemical engineering. In these application areas, the surface must be easy to clean every day and chemical cleaning agents must be frequently used.

4.. In public places, the surface of stainless steel is often scribbled, but an important feature of it is that it can be cleaned off, which is a significant advantage of stainless steel over aluminum. The surface of aluminum is prone to leaving marks, which are often difficult to remove. When cleaning the surface of stainless steel, it is necessary to follow the pattern of the stainless steel, as some surface processing patterns are unidirectional.

5.Stainless steel is most suitable for hospitals or other fields where hygiene conditions are crucial, such as food processing, catering, brewing, and chemical engineering. This is not only because it is easy to clean every day, sometimes chemical cleaning agents are also used, but also because it is not easy to breed bacteria. Experiments have shown that the performance in this area is the same as that of glass and ceramics.