Corrosion resistance, self - repair, environmental protection, long life, easy processing.

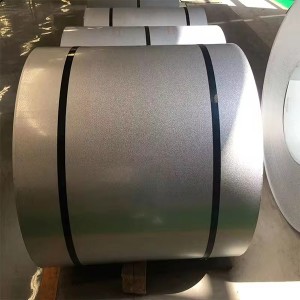

The alloy coating of galvanized aluminum magnesium steel plate is made of zinc (Zn), aluminum (Al), magnesium (Mg) after high temperature curing to form a dense ternary eutectic structure, so that the surface of the steel plate to form a layer of dense, effective corrosion prevention super coating.

Excellent corrosion resistance: In the case of the same coating is 5-10 times of the ordinary hot dip galvanized steel plate.

self-healing abilities: The cutting end face of Zinc-aluminum-magnesium steel plate and around the punching incision will be dissolved with the passage of time, forming a dense protective film composed of zinc hydroxide, acid zinc chloride and magnesium hydroxide. This protective film has low electrical conductivity and has obvious inhibitory effect on the corrosion of the section.

Excellent workability and damage resistance:Because zinc, aluminum and magnesium coating is very dense, smooth, coating surface hardness is 2.5 times that of ordinary galvanized, so that it has excellent tensile, stamping, bending, welding and other processing properties and excellent scratch resistance and wear resistance.

The environmental protection:Zinc, aluminum and magnesium surface treatment does not contain three, six valent Ming and other heavy metal ions, in line with international environmental protection (ROHS), is currently internationally recognized environmental products, in the field of environmental protection favored.