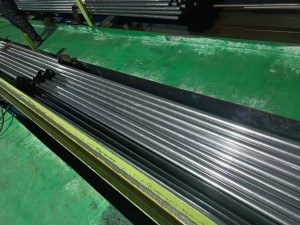

China Factory for SAE1020 SAE1045 SAE4140 SAE4340 SAE4145h High Precision Hot Rolled Cold Rolled Seamless Steel Honed Tube Round Steel Pipe

Short Description:

SAE 1020 Precision Seamless Steel Pipe is made through bright annealing or special cold rolling

processes.So SAE 1020 Precision Seamless Steel Pipe is a kind of seamless steel pipe which is designed with several advantages:

1.Inside and outside surface no oxide coating;

2. Bear high pressure, no leaking;

3.Surface smooth;

4.No reformation in cold bending, no cracks during flaring test, and flattening test.

5.Small tolerance ,within+/-0.05mm

With these advantages it is widely used for automobiles, motorcycles, electric power, machinery, hydraulic accessories, bearings, pneumatic components, oil cylinders, coal mines, transportation, boiler equipment, pipelines, engineering etc.

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of “quality initial, shopper supreme” for China Factory for SAE1020 SAE1045 SAE4140 SAE4340 SAE4145h High Precision Hot Rolled Cold Rolled Seamless Steel Honed Tube Round Steel Pipe, Standing still today and seeking into the longer term, we sincerely welcome customers all over the environment to cooperate with us.

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of “quality initial, shopper supreme” for China Welding Steel Round Pipe and Stainless Steel Round Pipe, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Dimensions : ASTM, ASME and API

Size : 10 mm OD to 89 mm OD

Wall Thickness : 1 mm to 8 mm

Length : Single Random, Double Random & Required Length

Schedules : SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Form : Round, Square, Rectangular, Hydraulic Etc

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

|

Grade |

C |

Mn |

Fe |

P |

S |

|

SAE 1020 |

0.170 – 0.230 |

0.300 – 0.600 |

99.08 – 99.53 |

≤ 0.040 |

≤ 0.050 |

|

Grade |

Tensile Strength |

Yield Strength |

Elongation |

|

AISI 1020 |

380 MPa, 55100 psi |

165 MPa, psi 29700 |

25% |

High dimensional accuracy for inside and outside diameters

Extremely limited wall thickness tolerances

Reduced eccentricity

Smooth drawn surface

Increased strength values due to cold forming

Tightly staggered range of dimensions

Customized heat treatment

Pipe Size is specified with two non-dimensional numbers:

Nominal Pipe Size (NPS) for diameter based on inches.

Schedule Number (SCH to specify the wall thickness of the Pipe.

Both the size and schedule are required to accurately specify a particular piece of pipe.

Nominal Pipe Size (NPS) is the current North American Set of standard sizes for pipes used for high and low pressures and temperatures. A further discussion of this is here.

Iron Pipe Size (IPS) was an earlier standard than NPS to designate the size. The size was the approximate inside diameter of the pipe in inches. Each pipe had one thickness, named (STD) Standard or (STD.WT.) Standard Weight. There were only 3 wall thicknesses at the time. In March 1927, the American Standards Association created a system that designated wall thickness based on smaller steps between sizes and introduced Nominal Pipe Size which replaced Iron Pipe Size.

Schedule Number for wall thickness ranges from SCH 5, 5S, 10, 10S, 20, 30, 40, 40S, 60, 80, 80S, 100, 120, 140, 160, STD, XS (Extra Strong) AND XXS (Double Extra Strong).

Pipe and Tubing Terms of Interest

BPE – Black Plain End Pipe

BTC – Black Threaded & Coupled

GPE – Galvanized Plain End

GTC – Galvanized Threaded & Coupled

TOE – Threaded One End

Pipe Coatings & Finishes:

Galvanized – Covered with a protective zinc coating on steel to prevent the material from rusting. The process can be hot-dip-galvanizing where the material is dipped in molten zinc or Electro-Galvanized where the steel sheet from which the pipe is made was galvanized during production by an electro-chemical reaction.

Uncoated – Uncoated Pipe

Black Coated – Coated with a dark colored iron-oxide

Red Primed – Red Oxide Primed used as a base coat for ferrous metals, gives iron and steel surfaces a layer of protection

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of “quality initial, shopper supreme” for China Factory for SAE1020 SAE1045 SAE4140 SAE4340 SAE4145h High Precision Hot Rolled Cold Rolled Seamless Steel Honed Tube Round Steel Pipe, Standing still today and seeking into the longer term, we sincerely welcome customers all over the environment to cooperate with us.

China Factory for China Welding Steel Round Pipe and Stainless Steel Round Pipe, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.