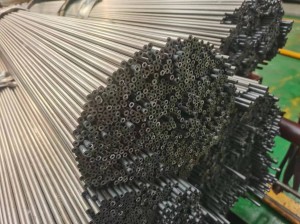

DIN high-precision precision drawn bright seamless steel pipe is made of Baosteel’s high-quality carbon steel material, which has undergone acid washing, precision drawing, non oxidation bright heat treatment (NBK state), non-destructive testing, high-pressure washing and acid washing of the inner hole of the steel pipe, anti rust oil treatment for the inner and outer walls of the steel pipe, and dust prevention treatment for both ends of the cover. The produced steel pipes have high precision and good smoothness. There is no oxide layer on the inner and outer walls of the steel pipes. The steel pipes can withstand the high pressure of liquid flow, and the steel pipes do not deform during cold bending. They can be expanded, flattened, and have no cracks. Mechanical performance can bend without deformation at any angle. Mainly used for preparing steel pipes in hydraulic system oil circuits, also known as hard piping in hydraulic systems, precision steel pipes for automobiles can meet the requirements of customers for high precision, smoothness, tensile strength, and mechanical properties of steel pipes.

Our company’s main products include: cold drawn or cold-rolled precision seamless steel pipes, bright seamless pipes and related bright oil pipes, seamless steel pipes for fluid transportation, with an annual output of over 3000 tons.