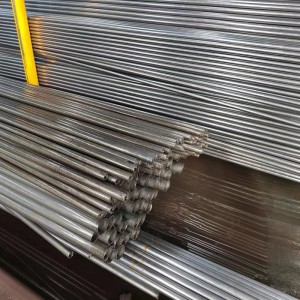

Factory directly Cold Drawn Precision Seamless Carbon Seamless Steel Tube

Short Description:

Precision Seamless Steel Piping for mechanical and light structural applications. This results in more uniform properties throughout the pipe compared to standard pipes. While mechanical tubes can be produced to standard specifications upon request, the “typical” properties typically produced focus on yield strength for precise dimensions and wall thicknesses. In some heavily formed applications, the yield strength may not even be specified and the mechanical tube is produced “fit for use”. Mechanical tubing includes a wide range of structural and non-structural applications.

We support our consumers with ideal top quality products and higher level services. Becoming the specialist manufacturer in this sector, we have now obtained prosperous practical working experience in producing and managing for Factory directly Cold Drawn Precision Seamless Carbon Seamless Steel Tube, We have confident that we can provide the high quality products at resonable price, good after-sales service to the customers. And we will create a bright future.

We support our consumers with ideal top quality products and higher level services. Becoming the specialist manufacturer in this sector, we have now obtained prosperous practical working experience in producing and managing for Cold Drawn Precision Seamless Steel Pipe, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

At Haihui Steel, we apply our metallurgical and production expertise to manufacture high-performance seamless mechanical pipe products to meet your needs.

This includes carbon, alloys and even custom steel grades; annealed, normalized and tempered; stress relieved and stress free; quenched and tempered.

Machinery and automotive seamless steel pipes for automobile skeleton and rear axle pipes, manufacturing and processing of precision equipment and instruments.

Application:

Backbone of Automobile and rear axle tube

Manufacturing and processing of precision equipments, instruments and apparatus

Delivery Condition: GBK, BKS, BK, BKW, NBK

Inspection and Test:

Chemical Composition, Mechanical Properties, Visual and Dimension Test, NDT, Grain Size Test

Surface Treatment:

Oil-dip, Varnish, Shot Blasting

|

Grade |

C |

Mn |

P≤ |

S≤ |

Si |

Cr |

Mo |

| 1010 | 0.08-0.13 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1020 | 0.18-0.23 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1045 | 0.43-0.50 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

|

Grade |

Condition |

Tensile strength |

Yield stength |

Elongation |

|

|

|

Mpa(min) |

Mpa(min) |

%(min) |

| 1020 | CW | 414 | 483 | 5 |

| SR | 345 | 448 | 10 | |

| A | 193 | 331 | 30 | |

| N | 234 | 379 | 22 | |

| 1025 | CW | 448 | 517 | 5 |

| SR | 379 | 483 | 8 | |

| A | 207 | 365 | 25 | |

| N | 248 | 379 | 22 | |

| 4130 | SR | 586 | 724 | 10 |

| A | 379 | 517 | 30 | |

| N | 414 | 621 | 20 | |

| 4140 | SR | 689 | 855 | 10 |

| A | 414 | 552 | 25 | |

| N | 621 | 855 | 20 |

Minimum Quantities

Hot-finished carbon and alloy—10,000 pounds, or 4,536 kilograms minimum.

Cold-drawn carbon and alloy—5,000 pounds minimum or 125 feet minimum, 2,268 kilograms minimum or 38.1 meters minimum, whichever is greater.

Quantity variation—standard ±10% of the ordered weight, or ±25 feet or 7.61 meters, whichever is greater.

Special Configurations

Tubular Products special seamless tubing configurations start with the highest quality steels. Grade, chemical analysis and surface condition are carefully considered, and production processes are tailored to achieve the best tubing for the end use.

The configurations are formed from round tube by cold drawing. The tube is drawn over a shaped mandrel or through a shaped die, or both. Improved tolerances, finishes and mechanical properties result.

Seamless and welded tubes for mechanical and general engineering applications. Tubes for construction and structural purposes such as civil structures, foundations, etc.

|

Standard |

Steel Grade |

|

| EN | 10297 | E355 |

| 10210-1/2 | S235JRH, S275JOH, S275J2H, S355JOH, S355J2H | |

| 10219-1/2 | ||

| DIN | 1629/2448 | St-52 |

| ASTM | A500 | Gr. A, Gr. B |

| A501 | ||

| A618 | Gr. I, Gr. II, Gr. III | |

|

Supply Conditions |

Steel Tubes Provided according to Outside Diameter and Wall Thickness |

Steel Pipes Provided according to Outside Diameter, Inside Diameter and Wall Thickness |

Steel Tubes with the Outside Diameter of 77 mm, Inside Diameter of 57 mm and the Wall Thickness of 10 mm |

||||

|

Allowable Deviation of Diameter and Wall Thickness |

Size (mm) |

Allowable Deviation (%) |

Size |

Allowable Deviation |

Size |

Allowable Deviation |

|

|

Outside Diameter |

±1.0 |

Outside Diameter |

±1.0% |

Outside Diameter |

+1.0 mm-0.55 mm |

||

|

Wall Thickness |

≤ 7 |

6 |

|||||

|

﹥7-15 |

2.5 |

Inside Diameter |

±1.75% |

Inside Diameter |

+1.5 mm-0.5 mm |

||

|

﹥15 |

5 |

Wall-Thickness-Difference |

≤ 15% of Nominal Wall Thickness |

Wall-Thickness-Difference |

≤ 15% of Nominal Wall Thickness |

||

We support our consumers with ideal top quality products and higher level services. Becoming the specialist manufacturer in this sector, we have now obtained prosperous practical working experience in producing and managing for Factory directly Cold Drawn Precision Seamless Carbon Seamless Steel Tube, We have confident that we can provide the high quality products at resonable price, good after-sales service to the customers. And we will create a bright future.

Factory directly China Import and Export Copper Coated Steel Pipe and Import and Export Pipe, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.