High Performance 40CR Alloy Steel Pipe - ASTM A335 Alloy Steel Seamless Pipe – Haihui

Short Description:

High Performance 40CR Alloy Steel Pipe - ASTM A335 Alloy Steel Seamless Pipe – Haihui Detail:

Strong resistance to rupturing at high temperatures and high pressures.

May be used for Hydrogen Sulfide Corrosion Services.

Resistant to cracking from hydrogen attack and embrittlement.

Resistant to hot sulfide corrosion cracking.

Can be used for NACE Applications where sour environments are under high temp and pressure.

Can be used in NACE-MRO 175 Sour Service.

Ideal for creep rupture applications.

Can handle high temperatures with very low elasticity.

The types of alloy steel covered by the ASTM A335 – ASME SA335 specification are designed with a “P” prefix, from P5 to P92. Grades P11/P22 and P91/92 are typically found in power stations, whereas grade P5 and P9 are more common for application in the petrochemical industry. Grades P9, P91 are, in the list, the more expensive

| ASTM A335Low-Alloy Steel(Grade) | UNS equivalent | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | – | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | – | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.02 | 0.01 | 0.5 | 8.50~9.50 | 0.30~0.60 |

| A335 Low-Alloy Pipe | UNS Number | Yield Strength ksi | Tensile Strength ksi | Elongation % | Hardness | |

| Rockwell | Brinell | |||||

| P1 | K11522 | 30 | 55 | 30 | – | – |

| P2 | K11547 | 30 | 55 | 30 | – | – |

| P5 | K41545 | 40 | 70 | 30 | – | 207 max |

| P9 | S50400 | 30 | 60 | 30 | – | – |

| P11 | K11597 | 30 | 60 | 20 | – | – |

| P12 | K11562 | 32 | 60 | 30 | – | 174 max |

| P22 | K21590 | 30 | 60 | 30 | – | – |

| P91 | K91560 | 60 | 85 | 20 | – | – |

Alloy Steel pipe are heat treated to achieve mechanical properties as per the desired alloying element. Below are some of the types of heat treatment.

Normalize Quench and Tempering.

Quench and Tempering.

Normalizing & Hardening.

Transverse/longitudinal: tension and flattening, hardness, bend tests- for material which has been heat-treated in batch furnaces, these tests shall be made on the 5% of the pipes from each heat lot number. For smaller lots, one pipe at a minimum has to be tested.

ASTM A335 Gr. P91 shall have a hardness of 250 HB / 265 HV (25 HRC).

Hydro testing: shall be applied to every length of pipe.

The non-destructive electric test is optional.

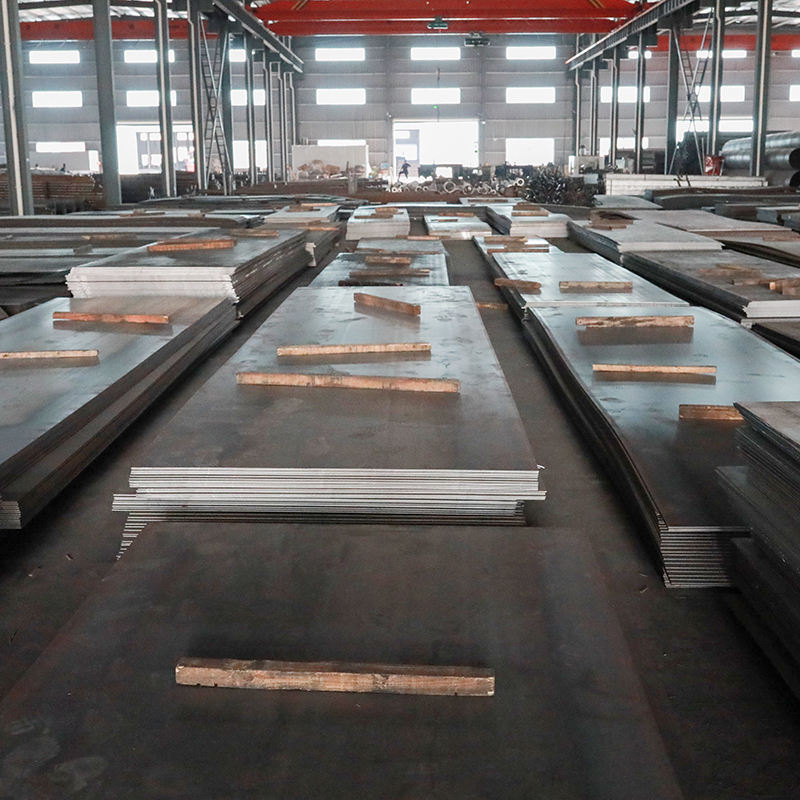

Product detail pictures:

Related Product Guide:

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for High Performance 40CR Alloy Steel Pipe - ASTM A335 Alloy Steel Seamless Pipe – Haihui, The product will supply to all over the world, such as: Japan, Czech, Ireland, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,