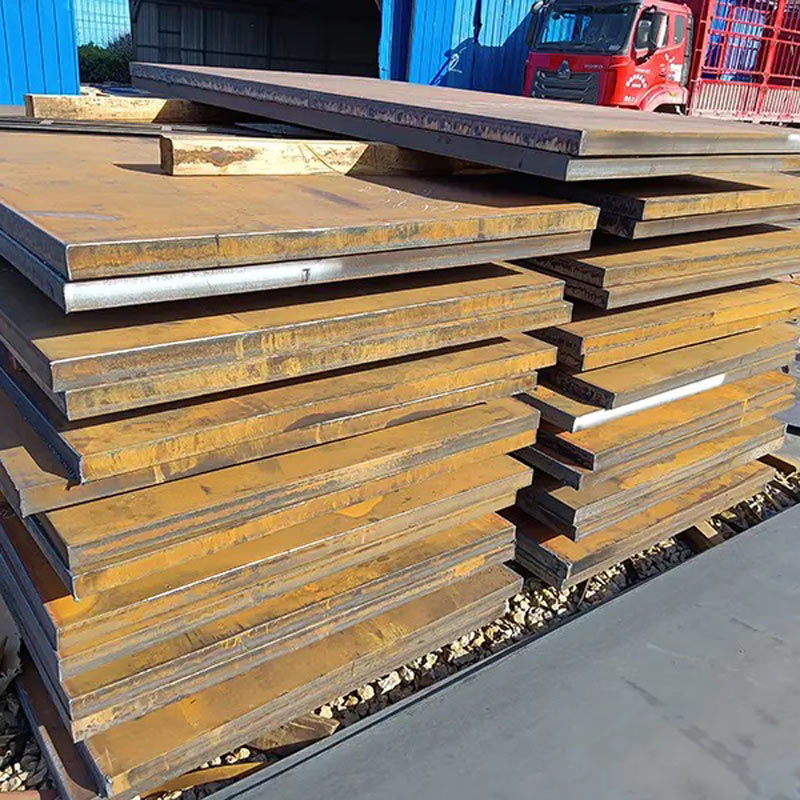

NM450 Hot Rolled Wear Resistant Steel Plate Abrasion Resistant Steel Sheet Low Alloy Carbon Steel Plate

Short Description:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We’re ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for NM450 Hot Rolled Wear Resistant Steel Plate Abrasion Resistant Steel Sheet Low Alloy Carbon Steel Plate, We always hold the philosophy of win-win, and build long-term cooperation relationship with customers from around the world.We believe that our growth base on customer’s success, credit is our life.

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We’re ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for NM450 Wear Resistant Steel Plate, We’ve customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don’t hesitate to contact us.

Wear-resistant steel NM450 is a high wear-resistant high-end varieties, with good cutting, bending, welding performance. Wear-resistant steel (Abrasion Resistance Steel ) is widely used in engineering, mining, construction and agriculture machinery products under extremely harsh working conditions with the requirement of high strength and high wear resistance, such as bulldozers, loaders, excavators, dump trucks and various mining machinery, etc. This kind of product has been mated for well-known domestic engineering machinery factories in mass as an ideal substitute of expensive imported wear-resistant plates.

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

B |

|

NM450 |

≤0.26 |

≤0.70 |

≤1.60 |

≤0.025 |

≤0.015 |

≤1.50 |

≤0.05 |

≤1.0 |

≤0.004 |

|

Thickness/mm |

ReL /MPa |

Rm /MPa |

A/% |

Hardness/ HBW10/3000 |

Impact -20℃ /J |

|

8 |

1250 |

1460 |

16 |

445 |

40 |

|

12 |

1290 |

1470 |

17 |

462 |

43 |

|

20 |

1370 |

1450 |

17 |

473 |

42 |

|

25 |

1230 |

1480 |

16.5 |

465 |

43 |

NM450 steel plates are abrasion resistance plate with great hardness. These are highly demanded in the fabrication industries. When imposed on reducing environments due to its resistant property these are prominent for reducing environments. These steel plates offer good weldability. These plates have an excellent finish which offers outstanding performance in oxidizing environments. The grade is blended with good resistance property towards corrosion. This serves high performance in reducing environments even at high temperatures. The grade is both magnetic and non-magnetic in nature. Steel plates resist distortion in terms of impact loading when the temperature gets higher.

Generally, plates have a uniform structure but to find the reliability of product manufactures conduct testing. Mostly IGC test, positive material test, mechanical test, hardness test, chemical test, pitting resistance test are performed. However, clients can demand any specific test as per their requirement. Additionally, third parties accomplish final inspection on NM450 steel plates for 100% quality assurance.

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We’re ISO9001, CE, and GS certified and strictly adhere to their good quality specifications.

NM450 Hot Rolled Wear Resistant Steel Plate Abrasion Resistant Steel Sheet Low Alloy Carbon Steel Plate

We always hold the philosophy of win-win, and build long-term cooperation relationship with customers from around the world.We believe that our growth base on customer’s success, credit is our life.

NM450 Wear Resistant Steel Plate

Our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don’t hesitate to contact us.