OEM/ODM Manufacturer ASTM A210 Boiler Tube – GB 5310 20G High Pressure Boiler Tube – Haihui

Short Description:

OEM/ODM Manufacturer ASTM A210 Boiler Tube – GB 5310 20G High Pressure Boiler Tube – Haihui Detail:

|

Grade |

C | Si | Mn | S | P | Cr | Mo | V | Ti | B | W | Ni | Al | Nb | N |

| 20G | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | 0.015 | 0.025 | ||||||||||

| 20 MnG | 0.17-0.24 | 0.17-0.37 | 0.70-1.00 | 0.015 | 0.025 | ||||||||||

| 25 MnG | 0.22-0.27 | 0.17-0.37 | 0.70-1.00 | 0.015 | 0.025 | ||||||||||

| 15 MoG | 0.12-0.20 | 0.17-0.37 | 0.40-0.80 | 0.015 | 0.025 | 0.25-0.35 | |||||||||

| 20 MoG | 0.15-0.25 | 0.17-0.37 | 0.40-0.80 | 0.015 | 0.025 | 0.44-0.65 | |||||||||

| 12CrMoG | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.015 | 0.025 | 0.40-0.70 | 0.40-0.55 | ||||||||

| 15CrMoG | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 0.015 | 0.025 | 0.80-1.10 | 0.40-0.55 | ||||||||

| 12Cr2MoG | 0.08-0.15 | ≤0.60 | 0.40-0.60 | 0.015 | 0.025 | 2.00-2.50 | 0.90-1.13 | ||||||||

| 12Cr1MoVG | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.01 | 0.025 | 0.90-1.20 | 0.25-0.35 | 0.15-0.30 | |||||||

| 12Cr2MoWVTiB | 0.08-0.15 | 0.45-0.75 | 0.45-0.65 | 0.015 | 0.025 | 1.60-2.10 | 0.50-0.65 | 0.28-0.42 | 0.08-0.18 | 0.002-0.008 | 0.30-0.55 | ||||

| 10Cr9Mo1VNbN | 0.08-0.12 | 0.20-0.50 | 0.30-0.60 | 0.01 | 0.02 | 8.00-9.50 | 0.85-1.05 | 0.18-0.25 | ≤0.040 | ≤0.040 | 0.06-0.10 | 0.03-0.07 |

|

Grade |

Tensile strength |

Yield point(Mpa) |

Elongation(%) |

Impact(J) |

|

(Mpa) |

not less than |

not less than |

not less than |

|

|

20G |

410-550 |

245 |

24/22 |

40/27 |

|

25MnG |

485-640 |

275 |

20/18 |

40/27 |

|

15MoG |

450-600 |

270 |

22/20 |

40/27 |

|

20MoG |

415-665 |

220 |

22/20 |

40/27 |

|

12CrMoG |

410-560 |

205 |

21/19 |

40/27 |

|

12 Cr2MoG |

450-600 |

280 |

22/20 |

40/27 |

|

12 Cr1MoVG |

470-640 |

255 |

21/19 |

40/27 |

|

12Cr2MoWVTiB |

540-735 |

345 |

18 |

40/27 |

|

10Cr9Mo1VNb |

≥585 |

415 |

20 |

40 |

|

1Cr18Ni9 |

≥520 |

206 |

35 |

|

|

1Cr19Ni11Nb |

≥520 |

206 |

35 |

|

W.T.(S) |

Tolerance of W.T. |

|

|

<3.5 |

+15%(+0.48mm min) |

|

|

-10%(+0.32mm min) |

||

|

3.5-20 |

+15%,-10% |

|

|

>20 |

D<219 |

±10% |

|

D≥219 |

+12.5%,-10% |

|

UT(Ultrasonic examination).

N(Normalized).

Q+T(Quenched and Tempered).

Z Direction Test(Z15,Z25,Z35).

Charpy V-Notch Impact Test.

The Third Party Test (such as SGS Test).

Coated or Shot Blasting and Painting.

GB5310 20G seamless steel pipes are mainly used for pressure vessels, machinery, pipe fittings, oil and chemical industry.

GB 5310 High pressure boiler tube Other Name

GB 5310 igh pressure boiler tube, 20G boiler steel pipe, 20G boiler pipe

Boiler tubing is used in these industries:

Steam Boilers.

Power Generation.

Fossil Fuel Plants.

Electric Power Plants.

Industrial Processing Plants.

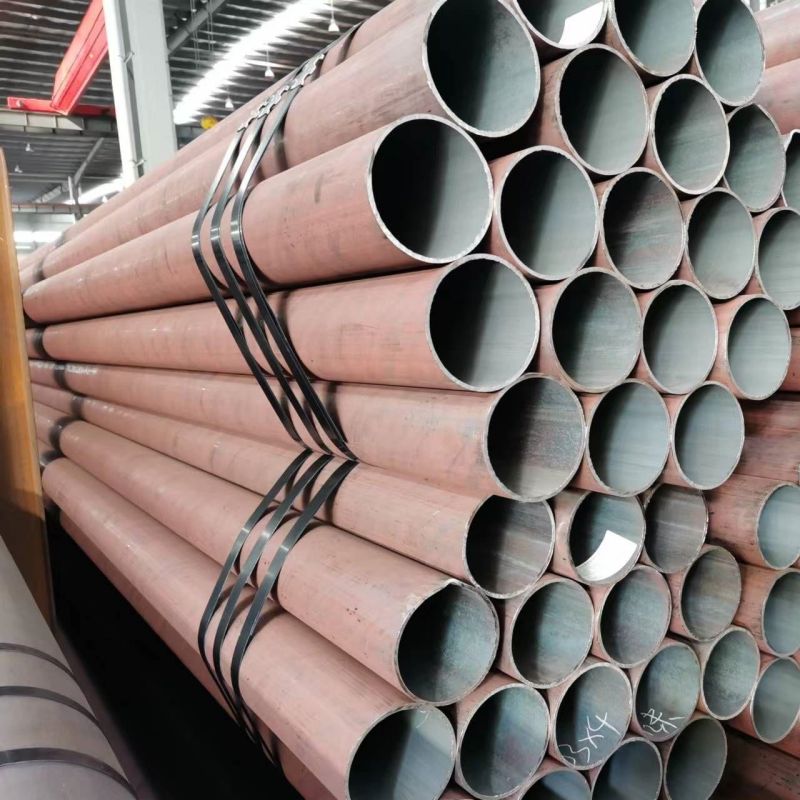

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for OEM/ODM Manufacturer ASTM A210 Boiler Tube – GB 5310 20G High Pressure Boiler Tube – Haihui, The product will supply to all over the world, such as: Nigeria, Greenland, Russia, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.